The Power of Performance Lubrication

Driving Industrial Efficiency Through Expertise

At Global Chemicals LLC, we understand that every rotating shaft, gear, and bearing in your plant relies on one thing 4 the quality of its lubrication. In today’s high-demand industrial world, equipment reliability defines operational excellence. Global Chemicals LLC stands as a trusted partner for industries that depend on precision, performance, and protection. For over a decade, we have supported oil & gas, power, mining, manufacturing, marine, and construction sectors with world-class lubricant solutions engineered for extreme conditions and continuous operation. Our comprehensive portfolio addresses every lubrication challenge your facility faces, backed by technical expertise that goes far beyond simple product supply.

The Scale Problem

Driving Industrial Efficiency Through Expertise

Everysingle day, mineral scalesilently accumulates in your pipes, membranes, and heat exchangers. It’s completely invisible at first4microscopic crystals forming layer by layer on metal surfaces. But by the time you notice reduced flow rates, increased pressure drops, or declining heat transfer efficiency, you’ve already lost thousands of dollars in operational efficiency. The insidious nature of scale formation means that prevention isn’t just good practice4it’s an economic imperative that directly impacts your bottom line. Water naturally contains dissolved minerals including calcium, magnesium, barium, and sulfates. Under specific operating conditions such as pressure changes, temperature increases, or pH shifts, these minerals exceed their solubility limits and precipitate as hard, crystalline deposits. This process, known as supersaturation, triggers rapid nucleation and crystal growth on any available surface. The result is a hard, adherent layer that reduces flow capacity, impedes heat transfer, and accelerates corrosion underneath the deposit.

Maintenance Reduction

Achieved through proper antiscalant implementation in

documented case studies

Energy Loss

Average efficiency decrease from

untreated scale formation in heat exchangers

Annual Cost

Typical maintenance expenses for medium-sized facility with scale problems

Prevention Rate

Scale formation prevented with correctly dosed antiscalant programs

The economic impact extends beyond immediatemaintenance costs. Uncontrolled scale formation leads to increased pumping costs due to flow restriction, premature equipment replacement, unplanned downtime during emergency cleanings, reduced product quality in manufacturing processes, and increased chemical consumption for reactive cleaning operations. For a typical industrial facility, these combined costs can exceed $50,000 annually4costs that are almost entirely preventable with proper scale management protocols.

The Chemistry Behind Scale Formation

Understandingscale formation requires examining theprecisechemical conditionsthat drive mineral precipitation. Scale forms when the ionic product of dissolved species exceeds the solubility product constant (Ksp) for a given compound. This supersaturation state is influenced by multiple interdependent variables including water temperature, pH levels, ionic strength, flow velocity, and surface

characteristics. Each type of scale has unique formation drivers and requires specific prevention strategies tailored to your water chemistry profile. Temperature plays a particularly critical role in scale formation kinetics. Most common scales, such as calcium sulfate and barium sulfate, exhibit inverse solubility4meaning they become less soluble as temperature increases. This explains why scale typically forms first on heat exchanger surfaces where temperatures are highest. Conversely, calcium carbonate shows increased solubility at higher temperatures but precipitates rapidly as water becomes more alkaline. Understanding these relationships allows engineers to predict scale formation locations and implement targeted prevention measures.

Supersaturation

Occurs when dissolved mineral

concentration exceeds solubility limits under specific temperature and pH conditions

Nucleation

Initial crystal formation begins on pipe walls, membrane surfaces, or suspended particles in the water

Crystal Growth

Existing crystals rapidly grow as additionalions attach to the crystal lattice structure

Deposit Formation

Mature scale layers accumulate, restricting flow and reducing system efficiency significantly

The rate of scale formation is also heavily influenced by hydrodynamic conditions. In areas of low flow velocity or turbulence, boundary layers develop where supersaturation can reach critical levels without the mixing effect that would normally disperse ions. Dead legs, valve seats, and areas downstream of bends are particularly susceptible. Additionally, surface roughness accelerates nucleation by providing crystallization sites, which is why even microscopic corrosion pits can trigger localized scale formation that rapidly propagates throughout a system.

Common Types of Scale and Their Characteristics

Not allscale is created equal.Each type of mineraldeposit has distinct chemicalproperties, formation mechanisms, and removal challenges. Identifying the specific scale type in your system is the critical first step toward implementing an effective prevention strategy, as each requires specialized approaches.

1

Calcium Carbonate (CaCO£)

Calcium Carbonate is the most common scale in brackish water systems and cooling towers, forming rapidly at alkaline pH. It appears as soft, acid-soluble deposits, making it the easiest to remove with simple acid cleaning. Prevention typically focuses on pH control and specific inhibitors.

2

Calcium Sulfate (CaSO¤)

Prevalent in high-TDS water sources like RO concentrate, Calcium Sulfate forms hard, adherent deposits, especially in heat exchangers due to inverse solubility. It’s not acidsoluble and requires specialized chemicals or mechanical removal. Effective prevention is crucial through proper antiscalant dosing.

3

Barium Sulfate (BaSO¤)

Barium Sulfate is the most challenging scale, forming irreversible, rock-hard deposits virtually impossible to remove chemically. Found in oilfield and deep well sources, its prevention with advanced, barium-specific antiscalants is absolutely mandatory, as there’s no effective cure once formed.

4

Silica (SiO¢)

Frequently encountered in groundwater and geothermal sources, silica forms unique glass-like deposits that are extremely difficult to remove without specialized chemicals like hydrofluoric acid. Temperature and pH significantly affect its solubility and polymerization. Prevention requires silica-specific inhibitor chemistry.

01

Extend Equipment Life

Reduce component wear and friction-related failures through advanced lubricant chemistry and proper application protocols.

02

Minimize Downtime

Prevent unplanned shutdowns and energy losses with predictive maintenance strategies and performance monitoring.

03

Enhance Safety & Compliance

Meet environmental and safety standards while protecting workers and equipment from hazardous failures.

04

Optimize Total Cost

Lower ownership costs through extended drain intervals, reduced consumption, and improved equipment efficiency.

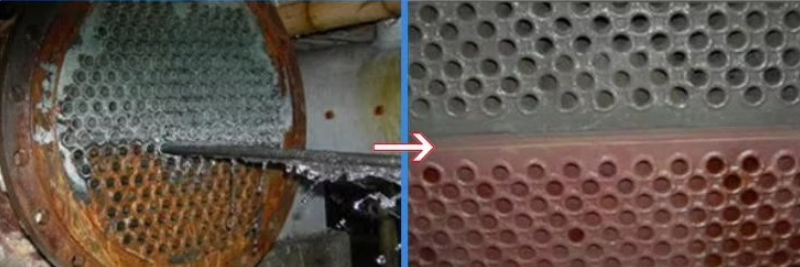

Real-World Success: 40% Maintenance Reduction Case Study

Facility Profile

A 500,000 gallon-per-day industrial reverse osmosis system treating high-hardness well water was experiencing chronicscaling issues. The facility was conducting membrane cleanings every six weeks at a cost of $8,000 per cleaning, including chemical costs, labor, and lost production time. Total annual maintenance costs exceeded $70,000, with declining permeate quality and increasing energy consumption between cleanings.

The Challenge

Water analysis revealed high concentrations of calcium (450 mg/L), alkalinity (350 mg/L as CaCO£), and sulfate (380 mg/L). The facility’s existing scale control program consisted of sporadic acid addition with no systematic antiscalant dosing. LSI calculations showed severe supersaturation with respect to calcium carbonate and calcium sulfate under operating

conditions.

This case study demonstrates the transformative impact of properly designed antiscalant programs. The

key success factors included accurate water analysis to identify specific scale threats, selection of appropriate antiscalant chemistry for the water composition, proper dosing equipment with reliable flowproportional control, ongoing monitoring and adjustment based on performance data, and commitment to preventive rather than reactive maintenance philosophy. The 40% reduction in maintenance frequency translated to substantial cost savings while simultaneously improving system reliability and product water quality.

How SOMICON Antiscalants Work

SOMICONantiscalantsemploy a sophisticated multi-pronged approach to combatscale formation in water systems. By understanding the intricate chemical processes that lead to mineral deposition, our formulations are engineered to disrupt scale at its earliest stages, ensuring optimal system performance and longevity. These mechanisms work synergistically to provide comprehensive protection against various scale types, even under challenging operating conditions.

Threshold Inhibition

SOMICON molecules effectively interfere with crystal growth at substoichiometric levels. Remarkably, just 2-5 ppm of our antiscalant can

prevent scale formation from water containing over 2000 ppm of scaleforming minerals, acting as a powerful preventative agent.

Crystal Modification

Our specialized antiscalants actively distort the natural crystalline structure of minerals. This modification creates weak, irregularly shaped particles that are easily dispersed and less prone to forming hard, adherent scale layers on surfaces.

Dispersion

Through the action of specialized polymers, SOMICON antiscalants keep suspended particles finely dispersed within the water. This prevents them from agglomerating into larger clusters and subsequently depositing onto system components, maintaining water flow and heat transfer efficiency.

Our product range is specifically designed to address diverse water treatment challenges. The following guide provides an overview of our key product series, helping you select the ideal solution for your specific application needs.

|

SOMICON BWM

|

Brackish water systems (TDS < 10,000 ppm)

|

Superior calcium carbonate inhibition, excellent iron control

|

|

SOMICON SWM

|

Seawater desalination systems

|

Effective sulfate scale control (calcium, barium, strontium)

|

|

SOMICON SWT

|

High-temperature thermal systems and boilers

|

Exceptional thermal stability, prevents silica and phosphate scale

|

|

SOMICON CWC

|

Industrial cooling water circuits

|

Combined scale and corrosion control, microbiological stability

|